What You Should Know About Custom Aluminum Extrusion Dies

Today, many architects, designers, and engineers specify custom aluminum extrusions for their building, construction and manufacturing projects. These extrusions offer more benefits than conventional materials while maintaining cost-effectiveness. The important thing for customers choosing a custom aluminum extrusion in Florida is to work with an experienced and reliable supplier. Offshore Direct Metals is an established custom aluminum extrusion supplier in Florida servicing a range of industries.

Aluminum extrusions are customized shapes, angles, and channels that offer material strength, durability, and long-term performance. Each extrusion is created by “force-feeding” aluminum through a die – very much like squeezing the toothpaste out from a tube.

The Role of an Aluminum Extrusion Die

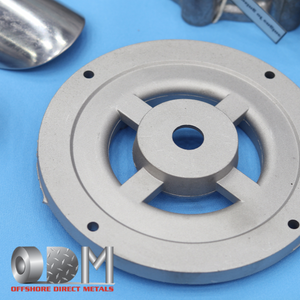

When fabricating an aluminum extrusion, the customized die is the actual “opening” through which the aluminum alloy material passes through to create the finished cross-sectional profile. Dies are made from high-strength metal that is resilient enough to endure the intense pressure of the extruding process. As the extruded aluminum emerges from the die, it’s a perfectly replicated cross-section of the original die pattern. Custom aluminum extrusion suppliers in Florida, customize dies to ensure orders of custom extrusions meet specific requirements and applications.

When fabricating an aluminum extrusion, the customized die is the actual “opening” through which the aluminum alloy material passes through to create the finished cross-sectional profile. Dies are made from high-strength metal that is resilient enough to endure the intense pressure of the extruding process. As the extruded aluminum emerges from the die, it’s a perfectly replicated cross-section of the original die pattern. Custom aluminum extrusion suppliers in Florida, customize dies to ensure orders of custom extrusions meet specific requirements and applications.

The Benefits of Using Customized Dies

Customized dies are the key to creating countless shapes, sizes and configurations of custom aluminum extrusions in Florida. These are highly engineered tooling components that allow for the most detailed and precise aluminum extrusion. Compared with other tooling options, extrusion dies and tooling are less expensive, thus making for cost-effective manufacturing. Most importantly, custom aluminum extrusion dies are produced once and used repeatedly.

Aluminum Extrusion Tooling and Dies

With aluminum extrusions, it's the custom tooling, and custom dies that provide the unique and distinctive profiles that many designers and engineers are looking for. When compared with other materials, the costs and lead times of custom tooling and dies is not a hindrance. In fact, the finished product offers exceptional results – fully customized design elements, much-enhanced functionality, and far better dollar value.

Three Types of Custom Extrusion Dies

There are essentially three types of aluminum extruded shapes – solid, hollow, and semi-hollow. Because each extrusion has specific characteristics, each requires a different die and tooling.

- Solid Dies: A solid die produces a shape that doesn’t have enclosed voids or openings. This includes solid bars, angles, and channels. A flat-face die has a flat face that matches the extrusion shape. A pocket die has a built-in cavity larger than the width of its profile. A feeder die has a feeder plate that is attached to it.

- Hollow Dies: Hollow extrusion dies feature at least one void that produces a desired shape. This would include rectangular tubes or multi-void T-Slots. In order to extrude a hollow shape, specific tooling is required. Precision and accuracy are the priority for designers and engineers specifying this type of custom aluminum extrusion in Florida.

- Semi-Hollow Dies: While similar to hollow dies, the voids in semi-hollow custom extrusion dies are not enclosed. Instead, there is an opening. As such, this die is often considered a hybrid between solid and hollow dies. Offshore Direct Metals, an established custom aluminum extrusion supplier in Florida, offers all three of the die options.