What is the Purpose of Aging Custom Aluminum Extrusions?

There are many production steps involved when ensuring the quality of a customized aluminum extrusion. Beyond the superior quality of the finished product, leading-edge aluminum extrusions meet exacting industry standards and strict performance expectations. For custom aluminum extrusions in Florida, customers can rely on Offshore Direct Metals for maximum results.

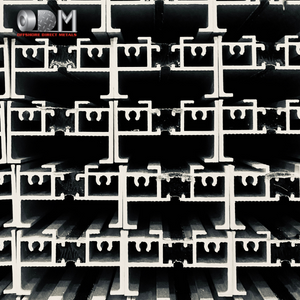

Offshore Direct Metals is an established custom aluminum extrusion supplier in Florida, offering a wide range of extruded profiles to numerous industry sectors. OD Metals delivers finished products to a wide variety of customers – from designers to engineers to architects to manufacturers. The aim, of course, is to deliver high quality along with optimum performance.

Why Aging is Used for Extruded Aluminum?

Aging is used in the production of aluminum extrusions for the purpose of enhancing the mechanical properties of the alloy material. And although aging will occur naturally over time, artificial aging (using heat treatment) is preferred because it takes substantially less time.

Aging is used in the production of aluminum extrusions for the purpose of enhancing the mechanical properties of the alloy material. And although aging will occur naturally over time, artificial aging (using heat treatment) is preferred because it takes substantially less time.

The aging process used by custom aluminum extrusion suppliers is also known as "age hardening.” It is designed to improve the tensile strength and yield stress of the finished extruded aluminum. “Natural” aging is not practical because of the inherent time delay and the downside for customers who need fast delivery.“Aging furnaces” are used during production to achieve the various product specifications that customers demand. Depending on the industry application, a designer will specify the needs of the project, and the aluminum extrusion supplier will reflect those needs in the finished product.

Enhancing Aluminum alloys by Tempering

One of the processes used for improving the mechanical properties of custom aluminum extrusions in Florida is known as “tempering.” The general idea behind tempering is to increase strength and hardness while reducing ductility. During the production process, an aluminum alloy will be subjected to one of 5 types of tempering.

- F As-Fabricated – which means no tempering

- O Annealed – only applied to wrought products

- H Work-hardened – an alternative to heat-treat

- W Solution heat-treated – then rapidly cooled

- T Thermally treated – as W followed by aging

Clearly, any type of enhancement will depend on the product application. For example, aluminum extrusions for a decorative application will require a different enhancement process than an aluminum extrusion used in a structural or load-bearing application. This is when solid advice from a reputable extrusion supplier can be valuable – and can benefit the final product significantly.

Where to Look for Top Quality Custom Aluminum Extrusions in Florida

As an established custom aluminum extrusion supplier in Florida, Offshore Direct Metals incorporates product knowledge and logistics experience to satisfy each customer’s demanding needs. We have a superb network of suppliers, each of which fulfills our high product standards, our requirement for just-in-time deliveries, and our objective to provide competitive pricing.

At OD Metals, we have established a proven “supply and demand” business model that allows our customers to reduce their production costs while increasing their profit picture. More than that, our personalized customer service approach is designed to reinforce business relationships while creating long-term partnerships that benefit everyone throughout the supply chain.